Panels and boards for the Klem connector

Are you looking for a flexible and innovative solution to realize partition walls, movable walls, exhibition walls or individual projects? We have the right panel connector for your project: You can buy the Klem panel connector and accessories right here in our online shop!

Our panel connector is designed to give you flexibility, stability and ease of use. But what kind of panels or boards can you use with our connector? Basic rule: Almost any panel material - as long as it is stable, resistant to bending and between 2 and 19 mm thick!

Our guide to panel materials and panel types will help you get the most out of the panel connecting system. Below we also list sources of supply, i.e. panel manufacturers and panel dealers, where you can buy panels individually.

Panel Guide - The right material for the Klem connector

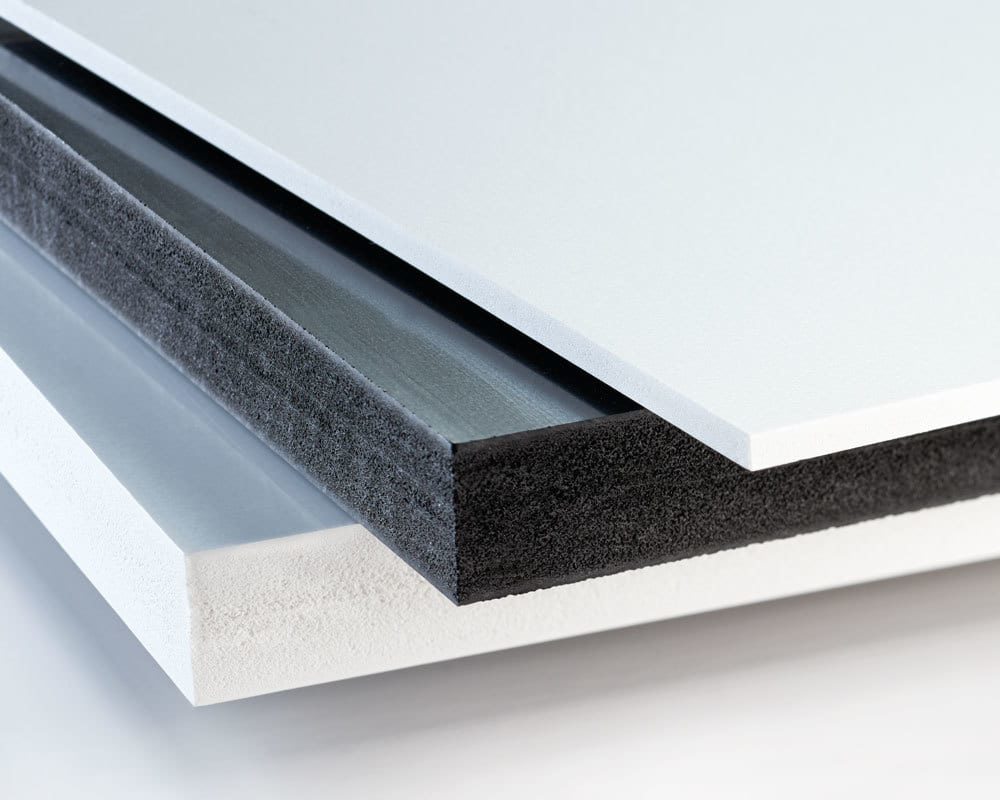

Rigid foam panels - always a good choice

Sheets of rigid foam are light, strong and relatively resistant. In the advertising industry they are used for the construction of displays and stands. They can be cut and milled, they can be printed and foiled. Rigid foam sheets are especially good for use with our Klem connector.

- Kömacel panels: This type of panel is made of polyvinyl chloride (PVC) in the so-called Celuka process. A key distinguishing feature is the rough edges, whereas its surface is firm and silky. The resistance and durability of Kömacel panels is unique, despite their light weight. Although they are robust, they are easy to work with.

- Forex sheets: These sheets are made of PVC similar to Kömacel and have a fine, homogeneous cell structure. They are closed-cell at the edges, but slightly softer than Kömacel sheets.

- Kapa boards: Lightweight foam boards made of polyurethane covered with cardboard or plastic layers. They are very easy to cut, have a low weight and yet are quite stable.

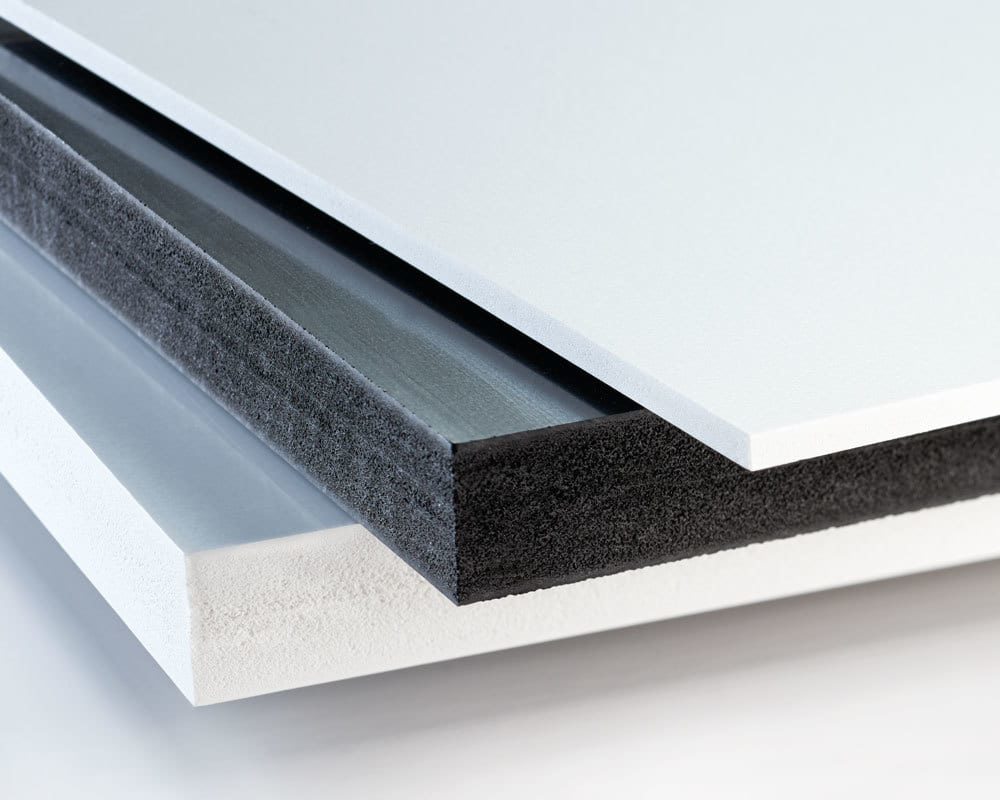

Honeycomb cardboard panels - the sustainable option

These panels are very light and yet have high stability. Because they are made of cardboard material, cardboard honeycomb panels are an environmentally friendly and cost-effective solution to all plastic panels. They are easy to cut and therefore ideal for fancy projects with our panel connector.

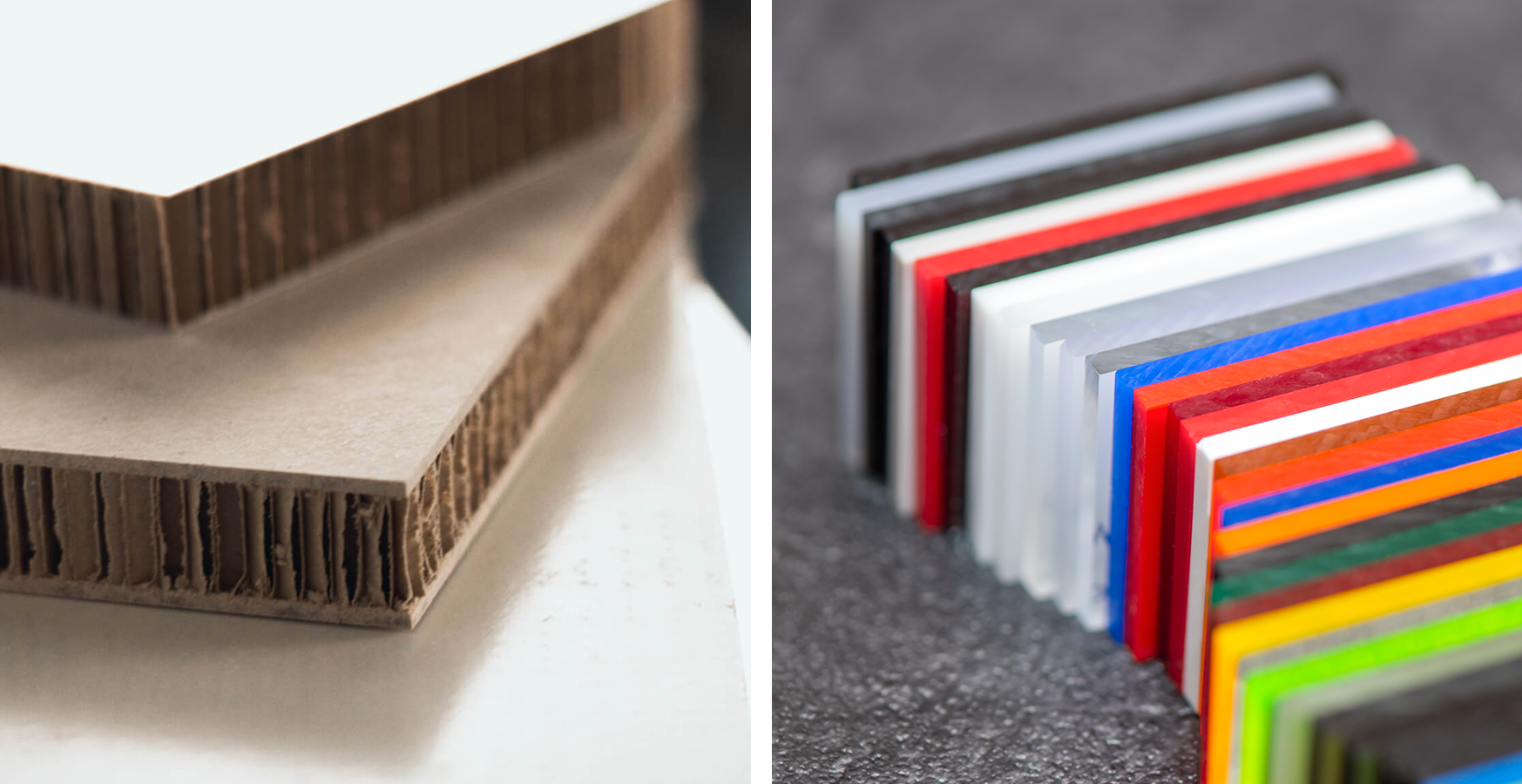

Acrylic glass and polycarbonate - when it should be transparent

Acrylic sheets and polycarbonate sheets both have high light transmission. They can be completely transparent or translucent. Double wall sheets and twinwall sheets are made from this material, which are wonderful for constructions with our panel connector.

- Acrylic glass sheets are often referred to as plexiglass or art glass and are visually similar to real glass. They are therefore often used as glass substitutes and, with our Klem Mini connector, allow functional constructions such as the building of showcases.

- Polycarbonate sheets are lighter and more flexible than acrylic, but more impact-resistant and therefore more break-resistant.

Unique constructions with the Klem connector!

You can find the right panel connector for unique constructions made of panels and boards here: Klem Connector and Klem Mini Connectoras well as matching picture lights right here in our online store!

Other panel types

- Aluminum sandwich panels: These panels are composed of three layers. A core of polyethene is reinforced by two outer layers of thin aluminum. These aluminum composite panels are strong, stable and robust, but the PE core makes them very light. They are also known as Alupanel panels or Alu-Dibond panels. The metallic look of these panels is unique, which makes them suitable for use with our panel connector.

- Polypropylene sheets: These plastic sheets are light and have good technical properties. A typical representative are Coroplast sheets - they are similar to polycarbonate twin-wall and double-wall sheets (see above).

- High Pressure Laminate (HPL) panels: HPL panels are very resistant and durable. They are ideal for use in demanding environments. These laminates are made from pulp (wood) and resin under high pressure and are impact and shock resistant.

- Hard PVC sheets: Compact PVC, also known as rigid PVC, has a higher dead weight than foamed PVC sheets (see above). The uniform surface of these compact, solid-colored PVC sheets can be matte or smooth.

Wood composite boards

- Chipboard (pressboard): They consist of more than 90% wood chips, which are pressed into boards with the help of binders. The rough surface with the recognizable wood parts gives an interesting contrast with our metal panel connectors.

- OSB boards (Oriented Strand Board): OSB boards are very similar to particleboard and are also called rough particleboard. Because they consist of three layers and their adhesive content is significantly lower than that of particleboard, they are more resistant to bending and more stable.

- MDF boards (medium density fiberboard): They are also made of compressed wood chips and glue, but the wood is more finely defibered. Therefore, they are usually more resistant to breakage and bending than OSB boards and have a more pleasant surface.

- Screen printing panels: These multiplex panels made of different types of wood are cross-glued from many veneer layers and are extremely stable. Because they are coated with phenolic resin, they are very weather resistant and have a homogeneous surface.

- Melamine boards: They combine a non-toxic chipboard inside with a robust melamine resin coating (synthetic resin). They are very stable and robust, but relatively heavy. They are often used in furniture construction.

Experimental possibilities

- Glass panels: Glass has excellent aesthetics and durability, but is very heavy and can break if not handled properly. Safety glass or tempered glass would be a good choice for use with the Klem connector.

- Metal panels: Steel, aluminum or copper is extremely resistant and durable. However, panels made of metal are heavy and require special tools for processing. For targeted use, however, certainly interesting!

- Stone slabs: Natural stones such as marble, granite, slate, but also tiles, earthenware or roof tiles offer diverse and appealing design options in conjunction with the Klem panel connector.

- Creative ideas: You can connect any materials with the Klem connector, as long as they are stiff and strong enough and do not exceed the thickness of 19 mm: We've seen constructions made of panels, dishes, records, and other art installations. Get creative!

"An impressive range of panel materials is available for use with the Klem connector. Success lies in selecting the right type of panel - we will be happy to advise you if necessary."

Theodor Puschkarski - The Inventor

Infinite possibilities

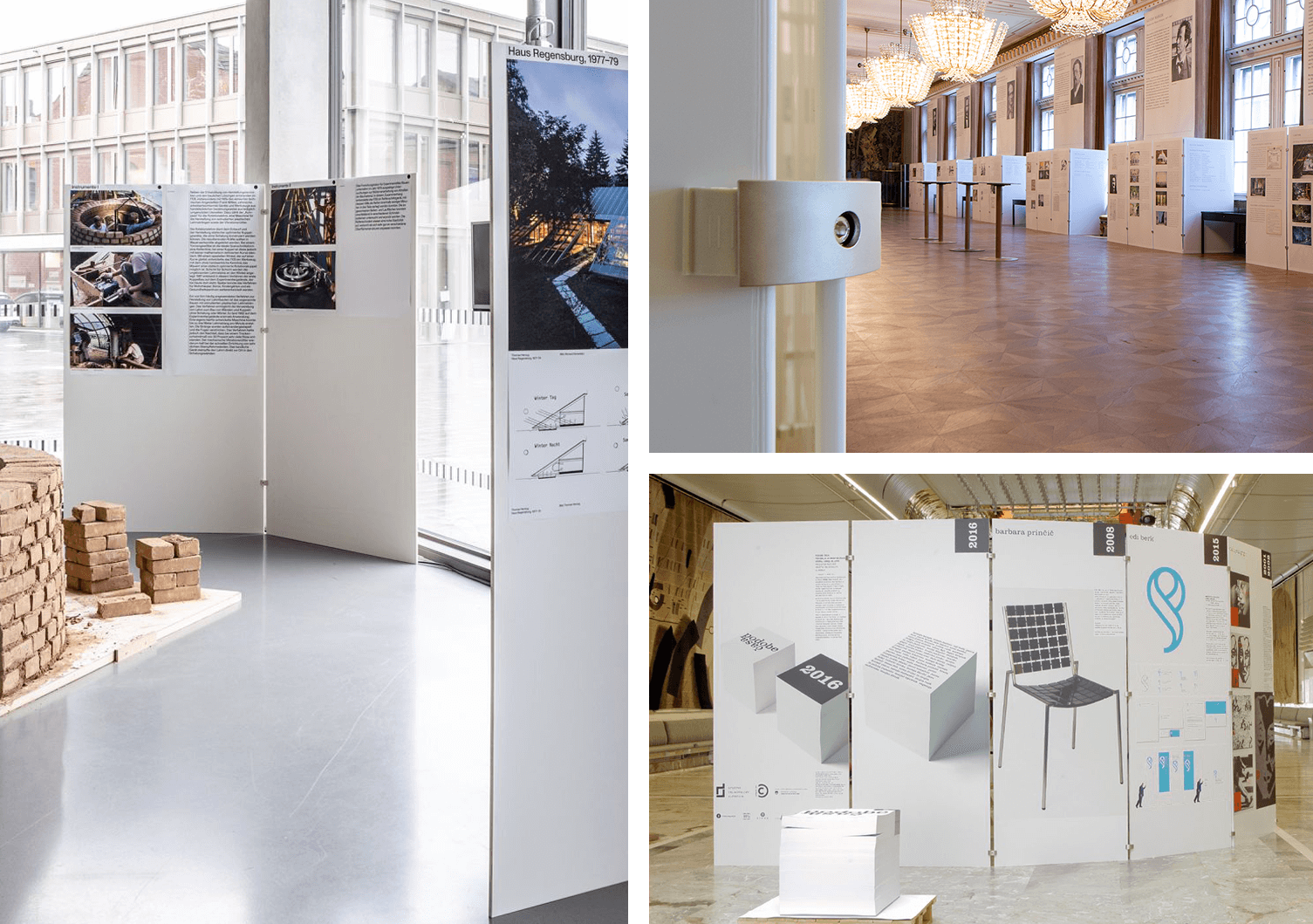

The Klem connector in use

In educational institutions

Whether school, preschool, or university: flexibility is the key to a successful exhibition or information event for you. With Klem you can build movable walls, room dividers, pedestals - arranged differently for every event!

In exhibitions

New concepts demand flexible walls, spaces, areas, partitions and dividers. Plus, with the Klem connector, you can build pedestals, columns, display cases, and custom structures easily, and modify them as many times as needed!

In trade fair construction

The Klem connector has revolutionized trade show booth construction! Build segregated areas, meeting areas and sensational constructions. Outfit your booth with counters, reception desks and seating areas!

Reference Projects

View specific applications our customers have implemented with the Klem connector.

FAQs - Frequently asked questions about panels and boards

Which panels do I use with the Klem system?

You can use almost any panel material with the Klem panel connector, as long as it is stable, resistant to bending and between 2 and 19 mm thick! Furthermore, it often depends on the aesthetics.

Do I need to process the panels before use with the Klem connector?

You do not need to drill, mill, saw anything. The Klem panel connector holds the panels very tightly over the silicone inserts. If necessary, grind or deburr the edges of the panels used and treat the surface as desired.

Can I combine different panel materials with each other?

Definitely! Often it is different materials with different surfaces and colors that make the appeal of a Klem installation.

Can I connect different panel thicknesses with each other?

To connect panels of different thicknesses with each other, you need to cut the duo rolls in half and insert two different ones into one connector each. The Klem connectors are suitable for panel thicknesses from 2 to 19 mm.

What to consider when mounting panels and connectors?

Work best in pairs, you need in principle only some skill and an Allen key. Please note our assembly instructions for constructing with panels and panels.

Can I buy panels and panels directly from KlemLighting?

We are working on it! Are you a panel dealer in Germany or Austria who would like to cooperate with us? Then let's discuss details with pleasure!

Panel materials to use with our Klem panel connector

Please note that the suitability of a particular sheet material for your particular application depends on many factors. What is the intended use? What are your environmental conditions? What are your individual preferences in terms of aesthetics, cost, weight and other factors?

Check the specific characteristics and requirements you have for the panels, and only then decide on a type of panel. If necessary, consult panel dealers or panel manufacturers before making a final choice - below we have listed sources of supply.

An informative overview of a wide variety of sheet materials for interior design, exhibition stand construction and store fitting can be found at Thyssen Krupp Plastics.

Where do I buy panels for the Klem panel connector?

You can find panels of all kinds in DIY stores and the building materials trade. Try locally or online at Hornbach, Obi, Hagebau, Bauhaus, Toom and home improvement stores near you.

Buy panels conveniently online

The following suppliers specialize in cutting panels to size. You can choose from a variety of materials and have them cut and delivered according to your individual needs. The website links below are mainly German websites.

Panels manufacturers and dealers - a selection

- www.interlux.at (DE/EN) is based in Austria and specializes in sustainable trade of high quality wood and board materials. Among them plywood, MDF, OSB. Tip: The translucent double-webbed boards.

- www.koemmerling.com (DE/EN) is a leading manufacturer of high-quality plastic products, including various types of boards. Tip: The rigid foam boards KÖMACEL 10 mm white and dark brown.

- www.alucobond.com (DE/EN) is a pioneer in the field of aluminum composite panels, known for their high quality, durability and versatility. Tip: The composite panels with aluminum face sheets and plastic core 06-10 mm.

- www.egger-holz.at (DE/EN) is an Austrian company specializing in wood products and wood processing. Tip: The chipboard and laminate panels 06-19 mm.

- www.mevaco.at is an Austria-based company specializing in the manufacture and sale of metal mesh and products. Expanded metal, perforated metal, etc. Tip: Perforated metal sheets folded to 10-19 mm.

- www.wettlinger.at is based in Austria and carries wood products as well as panel materials of all kinds. Tip: CELUKA rigid foam boards as used in our reference of the Vienna State Opera.

- www.swap-sachsen.de (DE/EN) produces ecological and sustainable honeycomb panels made of paper at its site in Saxony using state-of-the-art technology.

- www.ecofair.se (EN)is a Scandinavian company that produces, among other things, the sustainable Ecoboards, which consist of at least 92 % recycled paper.

- www.vomo-leichtbautechnik.de is a specialist in lightweight panels. The panels with paper honeycomb core and wood-based material layers on both sides can be customized.